Residential Elevators

Here you can find detailed information about residential elevators, including a listing of various manufacturers and various types of elevators.

First, lets discuss the big picture.

An Overview of Residential Elevators

Residential elevators will cost from around $10,000 to around $50,000, with most installations in the $20,000 to $30,000 range. The cost will depend on how high it goes, how many stops it can make, the size and load capacity of the cab, and the various amenities included.

However there is an additional cost not included in the above figures. The costs above are for the hardware and installation, but the elevator has to be installed in something. There will need to be an elevator shaft and perhaps an equipment room. That will require building costs. It is not a great cost. The footprint isn’t all that large compared to the size of an extra room, but it is extra space and construction that you will need to plan for.

There are a variety of technologies used in residential elevators. They represent tradeoffs in terms of initial costs, performance, noise and maintenance costs. Manufacturers will typically focus on one or a few of the technologies, but not all the options. Local dealers will offer only a handful of manufacturers. To see the full range of what is available you will need to cast a wide net.

When planning for your elevator consider the noise factor. Some systems are noisier than others. Some of this noise can be abated with good sound insulation. However the equipment will, in one way or another, be anchored into your building structure. This gives the opportunity for the sound to travel where you don’t want it to go. A good architect can help eliminate this problem, and good equipment will make a big difference as well.

The siting will also have an effect on how much this noise disturbs you. Having an elevator shaft next to your bedroom might be convenient, but you may find yourself awakened in the middle of the night by other users of the elevator.

Now, let us get into some specifics starting with the drive mechanism.

There are a whole lot of possible mechanisms for lifting an elevator, but there are a few basic drive systems that are used in most residential elevators.

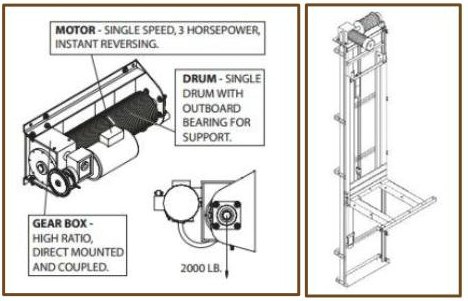

Cable Winding Drum Residential Elevators

In this system a motor turns a drum. The cable winds around the drum as it turns. As it is pulling the cable it pulls up the cab with it.

Usually the drum and motor are mounted on the top and there is a need for a little extra head room. However the cable can be routed back down the and the motor and drum could be in a pit below the elevator, or in a utility room off to the side.

Any system that uses a cable will experience some stretch of the cable over time. For this reason the cables get replaced every five years. This is an extra expense to consider with any systems that use cables.

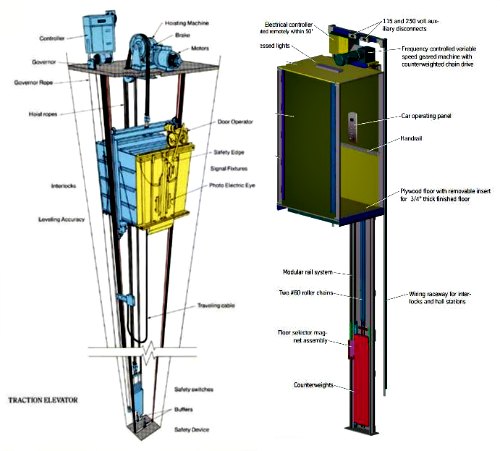

Chain-Drive Counterweight Residential Elevators

In a Chain-Drive Counterweight system a large weight travels in the opposite direction to the cab. If the cab is going up, the weight is going down. Since the weight counters the load of the elevator it is called a counterweight. The weight and the cab are joined with a chain. The chain goes up from the cab. At the top of the elevator track the chain goes over a toothed flywheel and back down to the counterweight.

If the cab and the counterweight weight the same then very little work is required to move the chain. Since the cab weight will vary, depending on if it is empty or full, there will be some effort required to move the elevator.

The cab is moved by having a geared-motor turn the flywheel so the motor is always mounted at the top of the shaft.

Since this system uses a chain rather than a cable the maintenance cost is lower. Chains will last 20 years or more, since they do not stretch.

Since power consumption is lower annual electrical costs are lower and the motor needed to drive the unit is smaller than with a cable winding drum system. However the frame has to be stronger since it is carrying twice the weight.

You may sometimes hear these elevators referred to as traction elevators. A traction elevator is a little bit broader classification as it would include elevators where a cable is used rather than a chain. It operates the same way, but since there are no links to engage a rope would tend to spin as a flywheel tried to drive it. The name comes from the fact that it requires traction on the cable if it so move the elevator. To create this traction the cable is wrapped around the flywheel more than once, turning it into a windlass.

In the residential market you tend to find chain-driven systems.

The pictures below show two variations of the traction elevator. The one on the left is a high-rise system using cable and pulling directly on the cab. The one on the right shows a residential elevator from Thyssen Krupp that uses a chain, with the connection to the cab made on the side.

Gearless Traction Residential Elevators

The gearless traction system is mechanically identical to the above systems except for the way the power is created and transmitted to the cable or chain. The above systems used geared motors. That is they have an electrical motor spinning at 3200 rpm, and that speed is geared down to a lower speed with a gear box (a transmission).

A gearless system uses a special low-speed motor and no gears. These have been around since about 1900, but there are a lot more low speed options available now, so it is a feasible option for a residential system. They really shine when you want to go fast, so they are less common in houses but do great in the taller buildings.

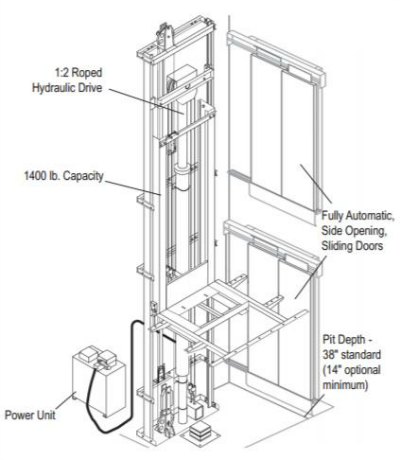

Hydraulic Drive Residential Elevators

In the simplest configuration a hydraulic ram pushes up on the cab directly. If the car needs to go up one floor a piston within the ram has to be pushed up one floor. This requires a very tall hydraulic unit. More common is to use pulleys to reduce the length required in the hydraulic unit.

Most people are familiar with how a block and tackle arrangement of pulleys is used to provide mechanical advantage. It allows someone to exert 100 lbs of force and lift 200 lbs. With more pulleys that advantage can go up many times. However, in the case of the 2:1 advantage it means I have to pull the rope 2 feet for the object to lift 1 foot. With elevators they reverse this.

They hook up the pulleys in such a way that the hydraulic ram will have to do 1000 lbs of effort to lift a 500 lb cab. The benefit is it will only have to travel half the distance. To push a car up one-story the piston will only extend out half-a-story.

This eliminates the problem of having to use an extremely tall ram, but it does add cable that has to be maintained. That means every five years the cable will need to be replaced, adding to the maintenance costs. However, it is possible to use chains in place of cables in this type of system, adding to the upfront cost, but reducing the maintenance.

There are two basic complaints about hydraulic elevators.

One, with any hydraulic system there is some leakage. Hydraulic fluid can be a little smelly. So it gets a little messy and stinky, and, if there is a rupture of a line, it can get very messy and stinky.

The second concerns efficiency. Hydraulic units are less energy efficient. You will spend more on electricity. Possibly several times more.

Part of the reason for the lower efficiency is that systems that use a motor to drive a chain or cable can also work as a generator when the elevator is descending. The elevator drives the motor and it creates electricity which feeds back into the power grid. This does not happen with a hydraulic elevator.

The second reason is that systems with counterweights don’t have to work as hard.

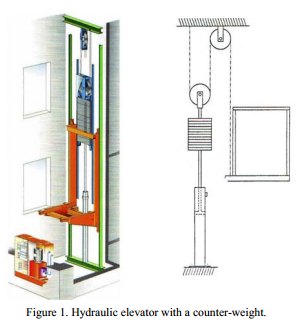

To counteract the efficiency problem some hydraulic units are made with counterweights. This doesn’t eliminate the efficiency gap, but it reduces it. A hydraulic system with a counterweight will use less electricity than its standard counterpart.

For residential customers the bigger concern is the smell and the leaks. I don’t want to scare anybody away. The hydraulic pump will be in a separate room and most that smell will not make it into the rest of the house, but for some people if only takes a little smell to make it a big concern.

The electrical usage is not a big concern simply because residential elevators do not get constant use. An elevator in a building is almost constantly in use and the electrical consumption is a big concern. Within a home there will only be a few people using it so most of the time it will be idle.

It is not that the electrical consumption is not a concern, but with the lower up front costs and the smooth ride that hydraulic drives offer it may be worth the higher operating costs.

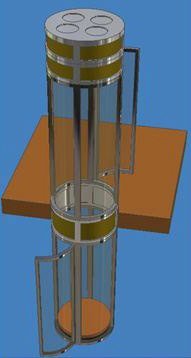

Pneumatic Vacuum Elevator

This type of elevator is completely different. You may have seen some in a hotel or at a mall. They are noteworthy because they are round and encased in glass. Essentially the car rides in a glass or plastic tube and there is nothing visible pushing the car or pulling the car.

What is really happening is that a vacuum is formed above the cab, pulling it up. Above the shaft a turbine spins and pulls air out of the shaft. The cab travels up until the pressure above reaches the pressure below the cab. When it is time to stop the turbine stops, but a one-way valve prevents the air from returning to the tube, so the cab stays in place. When it is time to descend air is allowed back in above the cab, but slowly so that the cab descends at a comfortable rate.

In the event of a power outage the system allows the cab to descend but it will not come back up.

There is little to maintain. Some cleaning is required periodically and seals could go bad over time. The biggest item to maintain is the turbine, which is essentially a motor with a fan.

These claim to be energy efficient, but I have yet to see a direct comparison with other systems, so I cannot vouch for that.

Pneumatic vacuum elevators tend to be pricey, but there is no need for a specially constructed shaft. The tube shaft is part of the system cost and is essentially free standing. In a situation where you have an open atrium it might be possible to install such a system and have the total lifetime costs lower than other systems. This is because you would forego the cost of the building a shaft and the maintenance costs are lower. The big caveat is the lack of information about energy consumption.

Pneumatic vacuum elevators look really nice. The glass cab gives a great view. In some cases they will fit in perfectly. Of course, if you are going for a traditional look having a space age glass tube in your living room may not seem like a good idea.

The downside aesthetically is the noise. In many household units the turbine is on top of the tube, inside the house. It is as loud as a garbage disposal.

The turbines can be housed away from the tube and connected to the unit with pipes. In which case the noise would probably not be a big concern.

Electrical Usage Comparison of Residential Elevators

A lot of factors go into energy consumption, including the type of motor used, whether doors are electrically operated and the efficiency of interior lighting.

When operating the gearless systems use much less electricity because there is no power lost to the gears. Geared systems with a counterweight are next most efficient. Cable Winding Drum systems are next most efficient. Hydraulic units without a counterweight are the least efficient. Without a counterweight they consume almost three-times more electricity than a gearless system, and twice as much as a geared counterweighted system. Adding a counterweight to a hydraulic system cuts the gap in half, but they are still less efficient.

Now, here is the secret that you need to know. Residential elevators get so little use that the unit is likely to use more power on standby than when it is operating and it is in this area that the gearless system have a big problem.

The gearless motors use frequency converters and these devices are on even when the elevator is not in use. As a result they are consuming lots of power while idle. Unless you think that you will be using the elevator a lot a geared system makes more sense and even a hydraulic unit might work out okay.

And if energy efficiency is a big concern make sure the cab has LED lights and manually operated doors.

Manufacturers of Residential Elevators

Within the residential market the elevator business is highly fractured. That means there are a lot of companies making residential elevators and selling elevators.

There are two basic types of manufacturers. There are the big boys who backed into the home market after they developed their expertise building commercial elevators.

Then there are the small potatoes who focused on making residential elevators as a primary business. It may not be their only business. Some of the elevator manufacturers came into it from the medical market and started out making stair lifts. These companies may no longer be small, but compared to the industrial giants like Otis Elevator they are baby companies.

I do not have the information to give a good comparison of these companies. I am simply listing the name of the company and a web address.

Before I do that let me state a few things. Most of the technology for residential elevators came from commercial elevators. The big players have the advantage in having developed this technology. However most of the technology is not all that new and it has dispersed. Lots of people have it. And many of the employees of the big boys go off and join the small potatoes and so the advantage isn’t all that great.

The small potatoes have an advantage in caring more for this market. Most are here to stay. Big players like Thyssen Krupp can leave the market and it barely gets a mention on their annual report. So you could say that the passion for this industry resides with the little guys.

In fact Thyssen Krupp did leave the field in August of 2012. Their website still reads like they are in business, but they aren’t.

I have seen some lists where the manufacturers that they list are actually value-added resellers or dealers. These guys spec out the system and may add some design value in trying to overcome structural concerns with the house, or in finishing out the cab, but they don’t make the elevator equipment. I have tried to screen these guys out. They are important and chances are you will buy through one of them, but there are so many that I decided to focus on the manufacturers and I will let them tell you who their dealers are.

List

|

Abbey Home Elevators Cambridge Elevating Inc. Custom Elevator Manufacturing Company, Inc. Garaventa Lift GCE Mfg., LLC

Lift-Avator, Inc. Mitsubishi Electric Otis Elevator Permatron Elevator, Inc. Pneumatic Vacuum Residential Elevators, Inc. Savaria Schumacher Elevator Co. Symmetry Elevator Solutions Tyler Elevator Products Waupaca Elevator Co, Inc. |

www.abbeyca.com www.CambridgeElevating.com www.customelevatorinc.com www.garaventalift.com www.gce-ResidentialElevators.com www.harmar.com www.liftavator.com www.mitsubishielectric-usa.com www.otisathome.com www.airrideelevator.com www.vacuumelevators.com www.residentialelevators.com www.savaria.com www.schumacherelevator.com www.symmetryelevator.com www.sematic.com www.waupacaelevator.com |

Wheelchair Platform Lift vs Elevator

Please!

New! Comments

Have your say about what you just read! Leave me a comment in the box below.