Chimney Design

This is the first page of a two-page article on chimney design. This page focuses on the functional aspects of design. Chimney aesthetics are covered on the second page.

A History of Chimney Design

Chimney design is a relatively new function for architecture. There was a time when the chimney was not. It did not exist. It seems so intuitive now, but prior to the middle ages a hole in the roof served as an outlet for smoke. In some cases people would heat or cook with charcoal, so there was little smoke inside, but for the most part it was just a smoky mess.

The Romans had the bright idea of having the fire detached from the house and drawing heated air into ducts running under the floor of their house, indirectly heating their house. This was a decent solution to the smoke problem, but the big step forward came about sometime in the middle ages. Someone had the bright idea of creating a chimney flue for channeling the smoke out of the house. Early chimney designs were inefficient, but were still a major improvement over directly venting into the house.

Along with the chimney came a change in the design of houses. The chimney made new designs possible. Most of your houses before chimneys were one-story. The roof would be steeply sloped to allow rain to run off the thatched roofs, but this also created a nice funnel shaped interior to assist in drawing the smoke upward to the smoke hole at the peak. Most of the smoke stayed in this roof area. The inhabited floor would smell smoky, but it was at least breathable air.

Up in the rafter meat and other perishables could be stored. The smoke would act to preserve them. Some loft area might be used for storage, or sometimes for sleeping areas, but it was definitely a less desirable accommodation.

With the invention of the chimney this attic area could now be used as a living area. Flooring could be laid across the beams creating a second floor, but also creating a flat ceiling for the first floor. Now I am not claiming that these horizontal ceilings were unheard of prior to the chimney. In places where flat roofed homes were possible the rooms below would naturally have had a flat roof, and in warm climate where heating was not such a concern multi-storied apartment buildings had existed for centuries. It was in Northern Europe where the climate required burning lots of wood to keep warm that the chimney had its largest effect on home design.

With the conversion of attic space from a smoke house to a second floor came the addition of dormer windows to bring in light. With the exclusion of smoke from the living area, the attitudes about the interior space began to change. When it became possible to keep the inside clean and nice, interiors started to become clean and nice. The insides began to be decorated and finished with more attention to beauty and cleanliness.

Chimney Design - Placement

Chimneys can either be placed along an outer wall, or they can be placed somewhere else, in the interior. The basic functional argument for having them along an exterior wall is that this makes the process of designing the interior layout easier and you don’t waste interior floor space. The argument for having them in the interior is that the escaping gases heat the chimney. If the chimney is inside the house much of that heat will remain in the house.

Another advantage of an interior chimney is a reduction in creosote. Creosote is the residue that condenses out of the smoke. If a hot combustion gas hits a cold chimney some of that gas will condense into a liquid and stick to the side of the chimney. If you have perfect combustion you won’t have this problem, but very few wood or coal fires can boast of complete combustion. So, an interior chimney will be warmer and there will be less creosote condensing onto the chimney.

Creosote is a problem for two basic reasons. First it builds up and restricts the flow of gas in the chimney flue. Second, it can be flammable. Under the right conditions it can catch fire, creating a dangerous chimney fire. While it sounds like the perfect place to have a fire, it can cause the roof to catch fire, or anything else that may touch the chimney at the hot spot.

Chimney Design - Size

Chimneys were originally bulky affairs. The openings tended to be oversized for the requirements. They remained this way for a long time. With experience they began to slim down, but the biggest change came with the invention of metal stoves and furnaces. The fireplace was an inefficient means of burning wood. The metal stoves that started being used in a big way in the 19th century were much more efficient. These produced less smoke and allowed for a slimmer chimney flue. They became even slimmer when oil and gas furnaces replace coal and wood.

From an early date chimneys started servicing more than one fireplace, but this created a danger where smoke from a downstairs fire could enter the upper floors through an upstairs fireplace. This problem was solved with individual flues within a single chimney. These could be formed by creating separate channels within the masonry, but ceramic flues were a better solution. You could house multiple flues within a single masonry opening.

Chimney Design - Chimney Flue Size

If your house is heated electrically it won’t need a chimney. If it relies on propane or natural gas the exhaust gases can be vented with a simple pipe exiting out of the wall. Systems using heating oil, coal or wood will require some kind of chimney. The size of the chimney flue will depend upon the requirements of the heating system. That system should specify the size of the flue required.

I heat with a wood-burning furnace. When I was looking at furnaces most required an eight inch flue. Some only required a six inch flue. The furnace I installed specified a chimney flue of at least 6 inches in diameter, but I installed an eight inch chimney liner, in case a future furnace might need the extra draw allowed by the larger flue.

The company I bought the liner from sold liners as small as 4 inches in diameter. These might be all that is required for a wood stove, or for a fuel oil furnace.

The chimney size is different than the flue size, and I will deal with flue size in the next section. A chimney might be much larger than an individual flue for several reasons. A chimney might have multiple flues, so it would need to be big enough to hold all the flues. It can also be bigger than it needs to be so that it can provide a thermal mass to hold the heat. A designer might also choose to make the chimney larger than it needs to be for aesthetic reasons.

Thermal mass just means that there is a lot of material that will hold heat for a while. A large thermal mass surrounding the chimney flues will continue to give off heat long after the fires have died down. This same mass will also hold heat from the warm day and release it during the cool night, so it can stabilize the temperature even when the stove or furnace is not in use.

The thermal mass is an advantage for an interior chimney only. Large chimneys on the outside walls of a house might look good, but they will not provide the benefit of heating the house.

A large chimney can provide the impression of solidity. This is especially true where the chimney material differs from the house siding. In the case of large chimneys on either end of a house the chimneys appear to buttress the house. It appears to be a much stronger house than if the chimneys were not there. Of course large can also appear clunky and may not be appropriate for that style of house.

Chimney Flues and Chimney Liners

The chimney is the brick, cement, or metal that forms the structure that supports the flue. The flue is essentially the tunnel in the middle of the chimney through which the gases flow. Often, when we refer to the chimney flue, we are talking about hollow ceramic block that stack on top of each other to form that tunnel. A chimney can support several flues in its interior.

Chimney flues can also be made from thin metal pipe, usually stainless steel, and then they are sometimes called chimney liners.

In my case I had an unlined chimney. The flue was simply the opening formed by the brick. Back in 1906 this was common, but it is dangerous. As the house ages cracks in gaps in the brick mortar can allow some gases to escape the chimney. During normal operation the flue gases will be sucked out of the chimney by the draw created by the heat. Gas won’t escape into the house. Rather air from the house will be sucked into the chimney.

Unfortunately normal isn’t the sole operating condition. Sometimes a back pressure situation can come about. This might be caused by swirling wind blowing down into the chimney, or because the fire has lost most of its heat and the draw disappears. In these cases flue gas can be forced through the crack and into the house, potentially poisoning the air with carbon monoxide or other dangerous gases.

My house was heated by either coal or fuel oil for about 100 years with this unlined chimney without a problem, but I knew the potential existed for a problem. I was also worried that a future engineering inspection for a house sale might reveal this flaw in my houses chimney design. When I installed my wood-burning furnace I made the decision to install a stainless steel liner.

I went with a flexible chimney liner. These come in large rolls. Installing requires straightening the tube out and feeding it down the chimney. In my case I built up a scaffolding up over the chimney to allow me to feed it down from above. In the video they show you how to do it, but they demonstrate with a four inch liner. An eight inch chimney liner fight you the whole way. You straighten out one end the and other curls up on you. It was pretty much a “Three Stooges” episode as I installed this (I played the role of all three). In retrospect I should have purchased the six-foot straight sections that snap together.

In the end I was successful. I now have a double-layer of protection. I have a stainless steel liner and also the original brick chimney. Any flue gas leaking out of the liner will just go up the gap between the liner and the chimney. It also reduces my risk of a chimney fire, since there is an air gap between any fire in the liner and chimney walls.

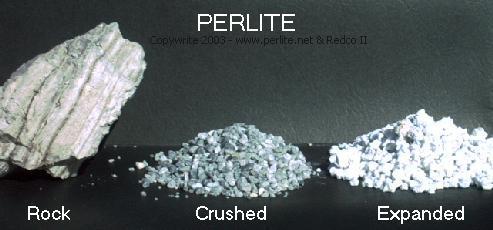

I did one other thing to make the chimney design more efficient. I filled the gap between the pipe and the chimney with loose perlite as a form of chimney insulation. I filled up the first eight feet or so, because this was all I had available. The perlite insulates around the pipe. Chimney insulation reduces the temperature differences between the flue gas and the liner so there is less creosote condensation. Of course you have less chimney heat escaping into the house, so there is a trade-off. Chimney insulation has to be resistant to very high temperatures.

Perlite insulation is a natural, loose, granular material that is heated with steam and then expands, rather like popcorn. It is an excellent type of chimney insulation because it will flow easily between the chimney liner and the chimney. However you should take appropriate safety measures. The perlite insulation will come with dust that is loose enough to get in your eyes and lungs and it is an irritant. Wear dust goggles and a dust mask. Perlite insultation is available at distributors of masonry and concrete products.

Insulated chimneys are rather rare. It requires a liner and space around that liner, and it is an added expense, so most engineers don't include it as part of their chimney design. However, an insulated chimney will have less creosote build up so there is less fire hazard. For some people that peace of mind is worth the expense.

Chimney Design- Insulated Stove Pipe

A chimney, with all its masonry, is a bulky thing. A stove pipe is relatively thin and light, but the old fashioned pipe, with its single wall of metal, is dangerous. It is too hot and can cause material nearby to catch fire. I am personally familiar with one house that burned down because the stove pipe became too hot.

This fire would have been prevented had he either used double-walled stove pipe or insulated stove pipe. The double-walled pipe is cheaper than the insulated stove pipe, but it is not as good and is not code approved for some applications in some areas.

The doubled wall pipe provides a blanket of air around the interior pipe and enforces a small standoff from the interior pipe. However you still have metal pipe in contact with room air which will cause the metal to be colder than the flue gas and will result in condensation and creosote.

The insulated stove pipe results in the interior pipe warming up to temperatures very close to the flue gas temperature. There is much less condensation. Building codes are much more accepting of insulated stove pipe. In many cases an insulated stove pipe, whether run on the outside or on the inside, can entirely replace a chimney. This is especially helpful where a wood stove is being retrofitted into a house that does not currently have a chimney. Insulated stove pipe, while not cheap, is almost always much less expensive than adding a chimney.

Chimney Design - Chimney Aesthetics

This article continues on with a discussion of the aesthetics of good chimney design.

To Top of Page - Chimney Design

To Next Page - Chimney Aesthetics

Home - House Design

Please!

New! Comments

Have your say about what you just read! Leave me a comment in the box below.