Fiberglass Siding

Fiberglass siding is one of the newest options available for cladding your house. It has many of the advantage of vinyl siding and fewer disadvantages, but is usually more expensive.

The image that might have come to mind when you first heard of fiberglass siding is the corrugated siding sometimes used on agricultural and industrial buildings. This siding is different. It looks much like wood siding. It has the same profile as wood lap siding and comes in the same basic dimensions. It is grained to look like wood. Most the siding products can make that claim, so I will not state that it is superior in looks, only that it can hold its own and you can decide if it looks better.

I say it is the newest, but it is also an old product. There was a siding made of fiberglass used years ago that could not compete against aluminum and vinyl, but the new product is very competitive.

Siding Properties

Vinyl siding is extruded. The vinyl is heated and pressed through a die into its profile shape. Fiberglass siding is pultruded. Fibers of glass are pulled through hot plastic that then goes through a die that gives it a profile shape. In both cases a slight texture is imprinted into the plastic/vinyl after it is extruded.

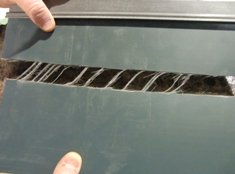

It is the fiberglass that provides the advantage. Plastics tend to expand with heat. It’s a small percentage, but over the length of a house that adds up to several inches of expansion. Glass fibers do not expand. Bound to the plastic they prevent the plastic from expanding. The expansion factor for siding containing fiberglass is about the same as for your windows, which is negligible. It has the lowest expansion factor of any of the artificial siding products.

Vinyl siding has special slots that are used with special fasteners to allow the vinyl to expand and contract. At the end of the siding, at the corners, wide vertical moldings are required to accommodate all that expanding and contracting. If you don’t like these wide corner boards then you definitely should consider other forms of siding.

Fiberglass, with little expansion, does not require these wide molding boards. It is treated as if it had no expansion. The boards are butted against each other and against any end boards. The seam is nearly invisible

Fiberglass is also strong, but as a siding it is not structural. It won’t hold weight, but it has sufficient rigidity to support its own weight. It will not sag. It is actually stronger than wood for an equivalent thickness, but fiberglass siding, like vinyl siding, is made very thin to keep the costs down, so its only strong if you compare it to a similar shaped product like vinyl siding. Vinyl sags, fiberglass doesn’t.

It is durable. Vinyl can be cracked and broken with stones thrown from a lawnmower. It can even be cracked with a good hard snowball if it is cold enough. Fiberglass is much tougher. It is its superior performance in extreme cold that makes it especially attractive in the northern states.

While it is designed to hold color forever, it can be painted. Like any plastic some preparation of the surface will help, but since it doesn’t expand you can use a wider variety of paint than is available for vinyl siding and it should adhere longer.

Fiberglass siding is supposed to have superior water management. All siding blocks most of the water, but strong winds, condensation, and snow conspire to allowing some water behind the siding. That is why you need a water barrier behind the siding.

I have heard some fiberglass siding proponents claim that this is not required with their products. I am skeptical and still would want this extra protection. The siding companies themselves do not make this claim. The cost is minor compared to the damage that can result if water gets into the structure of your house or into the insulation. However, I will concede that without the expansion that comes with vinyl a fiberglass siding should perform much better as a water barrier.

Siding for Do-It-Yourselfers

Vinyl has the advantage for the do-it-yourselfer. It is easy to cut, and there is a wealth of experience working with it. The fiberglass is more difficult to cut and there is less experience to draw on. However, a confidant and experienced handyman homeowner should still be able to apply fiberglass themselves.

The difficulty will be in getting a source of fiberglass siding for a DIY project. Within the vinyl market there is a lot of competition and many brand options. Fiberglass is newer and harder to find without going through an installer. In fact, I can only find two manufacturers for this product, Apex and Tecton, and I am pretty sure that one contracts from the other.

Both companies offer the siding in either a 4 inch lap, or a 7 inch lap. Apex offers 10 colors, but 4 of those are gray. Tecton offers 7 colors. These are the same colors as is offered by Apex, lacking only a gold and two grays.

Apex is owned by Marvin Windows. Tecton also manufactures fiberglass trim for doors. It sounds eerily similar.

This general lack of market penetration may mean that you can’t even find a contractor nearby, or that your contractor may have limited experience with this product. The lack of breadth in the market also means you have a limited choice of colors as compared to Vinyl. That is something you will have to determine, but I do recommend that you investigate if fiberglass siding is available in your area. I consider it the superior product and should be the standard against which the others are measured.

Return to House Siding

Return to House Structure

Home - House Design

Please!

New! Comments

Have your say about what you just read! Leave me a comment in the box below.